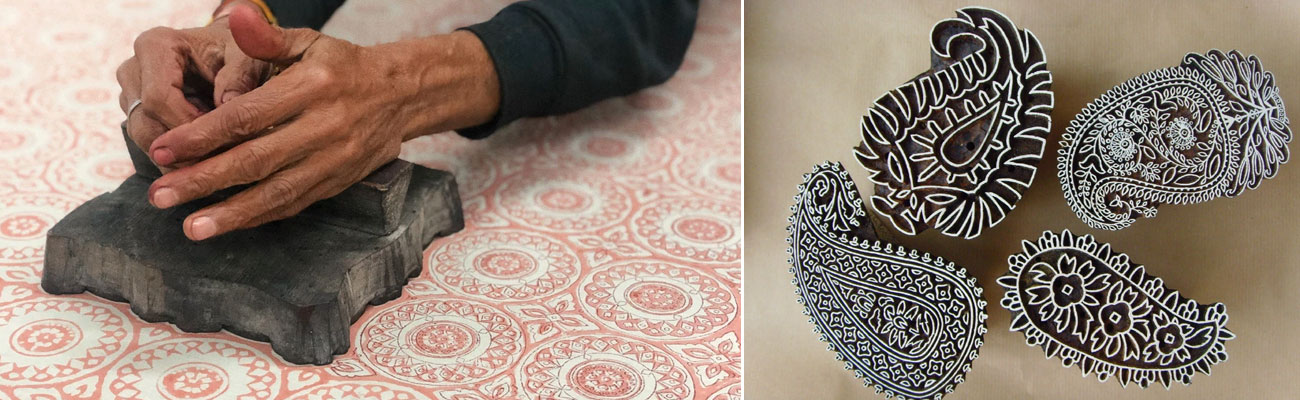

Hand Block Printing with wooden blocks, Box, lime, holly, sycamore, plane, or pear wood are used to make woodblocks for textile printing, with the latter three being the most popular. They come in a variety of sizes and thicknesses, but most are between two and three inches thick to avoid warping. Warping can also be avoided by using two or three pieces of cheaper wood, such as deal or pine, to support the chosen wood.

The tongues and grooves of the various pieces or blocks are tongued and grooved to fit together, and then firmly glued together under pressure to form one solid block, with the grain of each alternate piece running in a different direction. The block in question is relatively smooth and completely flat.

The template is then drawn or moved onto it. This is achieved by rubbing a tracing of the outlines of the design’s masses in lamp black and oil onto its flat surface. The parts that will be left in relief are then tinted with ammoniacal carmine or magenta between their outlines to separate them from the parts that will be cut away.

Since of distinct colour in the design requires its own special block, a separate tracing must be made of each and transferred (or placed on as it is called) to it. After receiving a tracing of the pattern, the block is thoroughly dampened and held that way during the cutting process by being covered with wet cloths. To avoid damaging the wood during the cutting of the coarser pieces, the block cutter starts by carving out the wood around the heavier masses first, then moves on to the finer and more delicate jobs.

Where a pattern contains wide areas of colour, the corresponding sections on the block are normally cut in outline, The object is filled in between the outlines with felt, which not only absorbs the colour better, but also provides a much more even appearance than a large surface of wood would. When the block is completed, it resembles flat relief carving, with the pattern sticking out like letterpress style.

In wood, fine details are extremely difficult to cut, and even when they are, wear down very rapidly or break off in printing. As a result, they’re almost always made of brass or copper strips bent to form and pushed edgewise into the flat surface of the stone. Coppering is the name for this process, and it allows for the printing of several delicate little forms such as stars, rosettes, and fine spots that would otherwise be difficult to achieve with hand or machine block printing.

Coppering is often frequently used to create a mould from which an entire block can be constructed and duplicated as many times as needed by casting. The metal strips are pushed to a predetermined depth into the face of a piece of lime-wood cut across the grain in this case, and once the entire design is completed in this manner, The block is placed, metal face down, in a tray of molten type-metal or solder, which transmits enough heat to the inserted portions of the copper strips to carbonise the wood in direct contact with them while also firmly attaching itself to the outstanding portions.

Textile stamping with stamps is classic and has transcended time to be useful in different industries such as fashion. The steps to do so are simple and as long as they are followed properly, the results will be unbeatable.

- Put the textile ink on the base of the stamp.

- Stamp the stamp on the fabric.

- Remove the seal and allow to dry.

- Iron using a stick or thin cloth between the iron and the stamped and ironed drawing. Do this for 3 minutes so that the ink adheres very well. Do not use steam.

It may seem like a manual and traditional process as it is extinct, but nothing is further from the truth. Stamping is one of the most common techniques even today in India, both accessories, garments and home textiles.

When the lime wood block is cold, a soft tap with a hammer on the back of the block quickly detaches the type-metal or alloy cake, as well as the strips of copper to which it is securely soldered, leaving a matrix, or mould, in the original design’s wood.

After cooling, the casting is made of a low melting-point alloy, It is then filed or ground until all of its projections are the same height and completely flat, then screwed onto a wooden support and ready to print. Similar moulds are often created by burning out the pattern lines with a red-hot steel punch that can be lifted or lowered at will, and then moving the block around by hand along the pattern lines.

They’re two to three inches thick, come in a variety of sizes, and are reinforced with two or more deal or pine wood bits. Fabric for the prints is laid out on flat tables, and hand block printing is completed.

Natural and vegetable dyes were previously used. Synthetic dyes, on the other hand, are commonly preferred today because they are widely available, much cheaper compared to natural dyes, and simple to use.

Special arrangements allow for very fine details to be etched and retained in the block. As a result, tiny stars and very minute patterns that would otherwise be impossible to achieve are available for fabric decoration. Some of the common motifs in block printed sarees include flowers, fruits, trees, birds, geometrical designs, and figurative patterns.